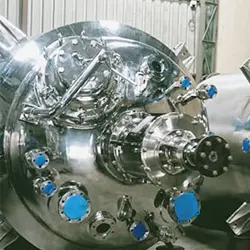

At PRS Technology, we deliver high-performance reactor systems engineered for demanding process applications across the pharmaceutical, chemical, agrochemical, and cosmetic industries.

Our systems are custom-built to meet stringent operational, safety, and regulatory standards, with an emphasis on precise mixing dynamics, uniform heat transfer, and robust construction.

Technical Specifications :::

- Working Volume Range: 20 Liters to 45,000 Liters

- Design Pressure: Standard up to 15 kg/cm² (higher ratings available for specific applications)

- Design Temperature: Up to 300°C, suitable for exothermic/endothermic reactions and thermal cycling processes

Material of Construction (MOC) :::

- Austenitic Stainless Steels: SS304, SS316, SS316L

- Special Alloys: Hastelloy C-22/C-276, Duplex SS (Alloy 2205), customized as per media compatibility

Agitation System :::

Designed based on rheological properties (viscosity, shear rate, flow regime) of the product

- Agitator Types: Anchor, Turbine, Propeller, Helical Ribbon, Pitched Blade Turbine, High Shear Disperser

- Mounting: Top-entry / Bottom-entry options

- Gear Drives: Inline, Helical-bevel, or Planetary gearbox options

- Seal Type: Single or Double Mechanical Seals (Dry running / Flush type, with gland arrangement as needed)

- Motor Classification: Flameproof / Non-Flameproof (Zone I & II compliant, ATEX or IECEx upon request)

Thermal Control System :::

- Heating/Cooling Jacket: Dimple Jacket / Conventional Jacket / Limpet Coil

- Media Options: Steam, Hot Oil, or Chilled Water

- Insulation: Mineral wool/ceramic blanket with SS cladding

Internal Design Features :::

- Baffle Arrangement: Typically 3 or 4 baffles (as per mixing Reynolds number) for enhanced turbulence

- Spray Ball / Rotary Jet Head (optional) for CIP (Clean-In-Place) & SIP (Sterilization-In-Place)

- Finish: Mirror / Matt / Electro-polished (0.2–0.6 Ra) based on application (sterile or industrial-grade)

Applications & Process Relevance :::

- Hydrogenation: High-pressure compatibility and gas dispersion efficiency

- Polymerization: Accurate thermal control and agitation uniformity

- Emulsification: High shear mixing for phase dispersion

- Crystallization: Controlled cooling profiles and nucleation control

- Suspension/Slurry Processing: Anchor/helical agitators for low to high viscosity media

- Heat-Sensitive Compounds: Gentle agitation, jacketed control zones

Note: All reactors are designed and fabricated in compliance with GMP / cGMP / ASME Section VIII Div. 1,